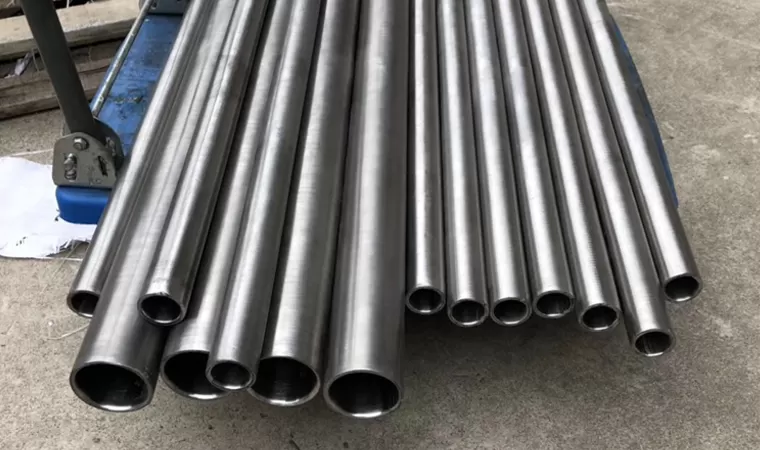

At Nascent Pipe & Tubes, we offer premium-grade Nickel 200 Tubes manufactured as per international quality standards, including ASTM B161 and UNS N02200. These tubes are highly recognized for their exceptional thermal and electrical conductivity, outstanding resistance to caustic alkalis, and excellent mechanical strength across various industrial applications. Nickel 200, a commercially pure wrought nickel with a minimum of 99.6% nickel composition, is ideal for critical applications that demand purity and corrosion resistance.

The Nickel 200 Tubes manufactured by Nascent Pipe & Tubes conform to global standards such as ASTM B161 and ASTM B725, which ensure dimensional accuracy, pressure tolerance, and durability. These standards regulate both seamless and welded forms of Nickel 200 Tubes. The material's UNS number, UNS N02200, identifies it as commercially pure wrought nickel with a minimum nickel content of 99.6%. The low carbon content of this alloy enhances its resistance to graphitization, making it suitable for temperatures up to 600°F (315°C). Its ferromagnetic nature and outstanding workability allow easy machining, fabrication, and welding, giving our pipes added versatility.

Nickel 200 Tubes Manufacturers, Nickel 200 Tubes Suppliers, Nickel 200 Tubes Stockists, Nickel 200 Tubes Exporters

Nickel 200 Tubes Manufacturers in India, Nickel 200 Tubes Suppliers in India, Nickel 200 Tubes Stockists in India, Nickel 200 Tubes Exporters in India

The universal standard name for these products is Nickel 200 Seamless Tubes, manufactured using cold-drawn or hot-finished methods. The tubes are available in a range of wall thicknesses and diameters to suit diverse industrial needs. Our manufacturing process ensures a smooth internal finish and tight dimensional tolerances, which improve flow rates and minimize system contamination, making them suitable for high-purity applications.

Nickel 200 Tubes Manufacturers in Mumbai, Nickel 200 Tubes Suppliers in Mumbai, Nickel 200 Tubes Stockists in Mumbai, Nickel 200 Tubes Exporters in Mumbai

The UNS N02200 Tubes offered by Nascent Pipe & Tubes exhibit superb resistance to dry fluorine, hydrochloric acids, and other alkaline solutions. They are often chosen for heat exchangers, marine engineering, chemical handling systems, and food processing equipment. Due to their low carbon content, Nickel 200 tubes offer enhanced resistance to graphitization, maintaining structural integrity in high-temperature environments.

Nickel Alloy 200 Tubes Specification

ASTM Specification :ASTM B161 ASME SB161 UNS N02200

Standard : ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB

ASTM B161 Nickel 200 Seamless Pipe Size :4 to 219mm W. T.: 0.5 to 20mm

UNS N02200 Welded Pipe Size :5.0 - 1219.2 mm

Nickel WERKSTOFF NR. 2.4066 EFW Pipe size :5.0 - 1219.2 mm

Swg & Bwg : 12 Swg., 10 Swg., 16 Swg., 14 Swg., 20 Swg., 18 Swg.,

200 Nickel Pipe Schedule :XS, SCH30, SCH40, XXS, SCH80, SCH120, SCH60, SCH140, STD, SCH10, SCH10S, SCH40S, SCH80, SCH20, SCH5, SCH160

Nickel 200 pipe Length :Double Random, Single Random, Standard & Cut length Pipe

Finish :Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish, etc

Form :Nickel 200 are available in form of Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc.

Type of 200 Alloy Pipe :Seamless / ERW/ EFW / Welded / Fabricated / CDW / DOM / CEW nickel 200

Nickel 200 pipe End :Plain End, Beveled End, Treaded Pipe, Screwed ends

Marking on Alloy 200 Pipe :All ASTM B161 Nickel 200 Tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.)

Application of Nickel 200 pipe :Dairy Pipe, Oil Pipe, Gas Pipe, Fluid Pipe, Boiler Pipe for Chemical Industry

Value Added Service :Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc.

Specialize in :Large Diameter Nickel 200 pipe

Nickel 200 pipe manufacturing Technique :Cold drawn, hot drawn, bright annealed, solid solution, hot extruding

Our stockyard :Chennai, Mumbai, Agra, Noida, Shivamogga, Ahmedabad, Bhubaneswar, Tirunelveli, Thiruvananthapuram, Pune, Bengaluru, Hyderabad, Tiruchirappalli, Dhanbad, Coimbatore, Navi Mumbai, Pimpri-Chinchwad,

Nickel 200 pipe Test Certificate :Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection

Material Test Certificates (MTC) :Material Test Certificates (MTC) as per EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2, 100% Radiography Test Report, Heat Treatment Charts, Raw Materials Certificate, Third Party Inspection Report, Fumigation Certificates, Nickel 200 HS Code Commercial Invoice, Form A for Generalized System of Preferences (GSP)

Manufacturers of Nickel 200 pipeNickel 200 Pipe make Sumitomo Metals, JapanAlloy 200 Pipe make Schoeller Bleckmann, AustriaNickel 200 Pipe make Sanyo Special Steel, Japan Nickel 200 Pipe make Nippon Steel Corporation, Japan Alloy 200 Pipe make Kobe Special Tube, Japan Alloy 200 Seamless Pipe make Seah Steel Corporation, Korea Nickel 200 Pipe make Tubacex Tubos Inoxidables S.A., Spain

We can also cut, thread, and groove UNS N02200 Pipe to meet your specifications. Nickel 200 pipe Dimension ANSI/ ASME B36.10, B36.19, B2.1

Our Export

Domestic Area

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |