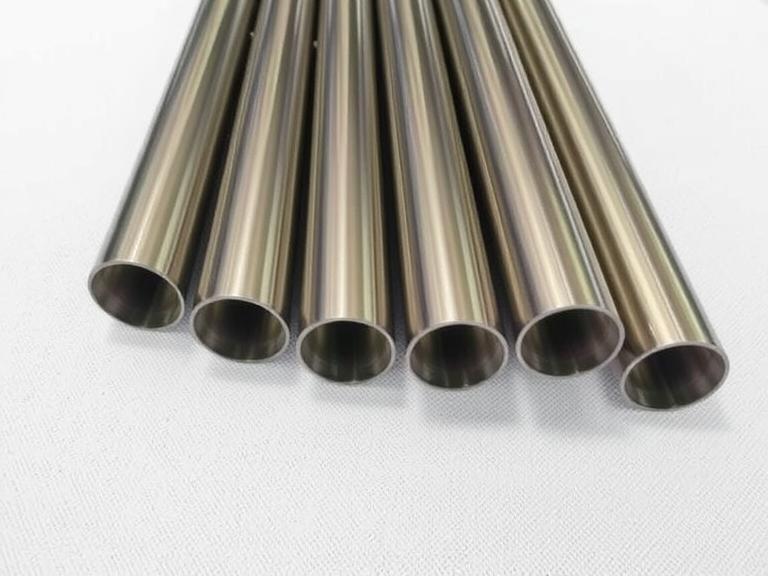

Nascent Pipe & Tubes is a leading supplier and stockist of premium quality Stainless Steel 904L Tubes, catering to industries across the globe. Stainless Steel 904L, designated by UNS N08904 and conforming to ASTM B677, is a non-stabilized austenitic stainless steel known for its superior resistance to corrosion, especially in harsh environments involving sulfuric and phosphoric acids. Our tubes are manufactured to comply with international standards such as ASME SB677, DIN 1.4539, and EN 10216-5.

Our 904L stainless steel tubes are highly acclaimed for their exceptional performance in applications demanding resistance to stress corrosion cracking, crevice corrosion, and pitting. This grade contains a high amount of chromium, nickel, molybdenum, and copper which enhances its corrosion resistance, making it suitable for chemical processing plants, heat exchangers, marine applications, and oil & gas refineries.

Stainless Steel 904L Tubes Manufacturers, Stainless Steel 904L Tubes Suppliers, Stainless Steel 904L Tubes Stockists, Stainless Steel 904L Tubes Exporters

Stainless Steel 904L Tubes Manufacturers in India, Stainless Steel 904L Tubes Suppliers in India, Stainless Steel 904L Tubes Stockists in India, Stainless Steel 904L Tubes Exporters in India

Nascent Pipe & Tubes ensures each tube is produced using precision technology and inspected under stringent quality parameters to deliver long-term operational durability. These ASTM B677 Stainless Steel 904L Tubes offer excellent weldability, formability, and toughness, even under cryogenic temperatures. With smooth internal and external surfaces, our tubes are perfect for instrumentation, hydraulic systems, and high-pressure applications.

Stainless Steel 904L Tubes Manufacturers in Mumbai, Stainless Steel 904L Tubes Suppliers in Mumbai, Stainless Steel 904L Tubes Stockists in Mumbai, Stainless Steel 904L Tubes Exporters in Mumbai

As a trusted manufacturer and exporter of 904L Stainless Steel Tubes, Nascent Pipe & Tubes guarantees consistent supply with on-time delivery and competitive pricing. Our tubes are widely demanded in pharmaceutical, pulp & paper, seawater treatment, and power generation sectors for their unmatched metallurgical properties and reliable performance under corrosive conditions.

Specification of Stainless Steel 904L Seamless Tubes

Stainless Steel Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size :1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Tubes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Tubes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Stainless Steel 904L Seamless Tubes

| C | Mn | Si | P | S | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|

| 904L | 0.07max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 | min: 8.0 max: 10.5 | — |

Mechanical Properties Of Stainless Steel 904L Seamless Tubes

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 904L | 75 | 30 | 40 | 201 | 92 |

Physical Properties of Stainless Steel 904L Seamless Tubes

| SS 316 | ||||||

|---|---|---|---|---|---|---|

| Density lbm/in3 | Thermal Conductivity (BTU/h ft. °F) | Electrical Resistivity (in x 10-6) | Modulus of Elasticity (psi x 106 | Coefficient of Thermal Expansion (in/in)/ °F x 10-6 | Specific Heat (BTU/lb/ °F) | Melting Range (°F) |

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

Equivalent Grades Stainless Steel 904L Seamless Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Our Export

Domestic Area

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |