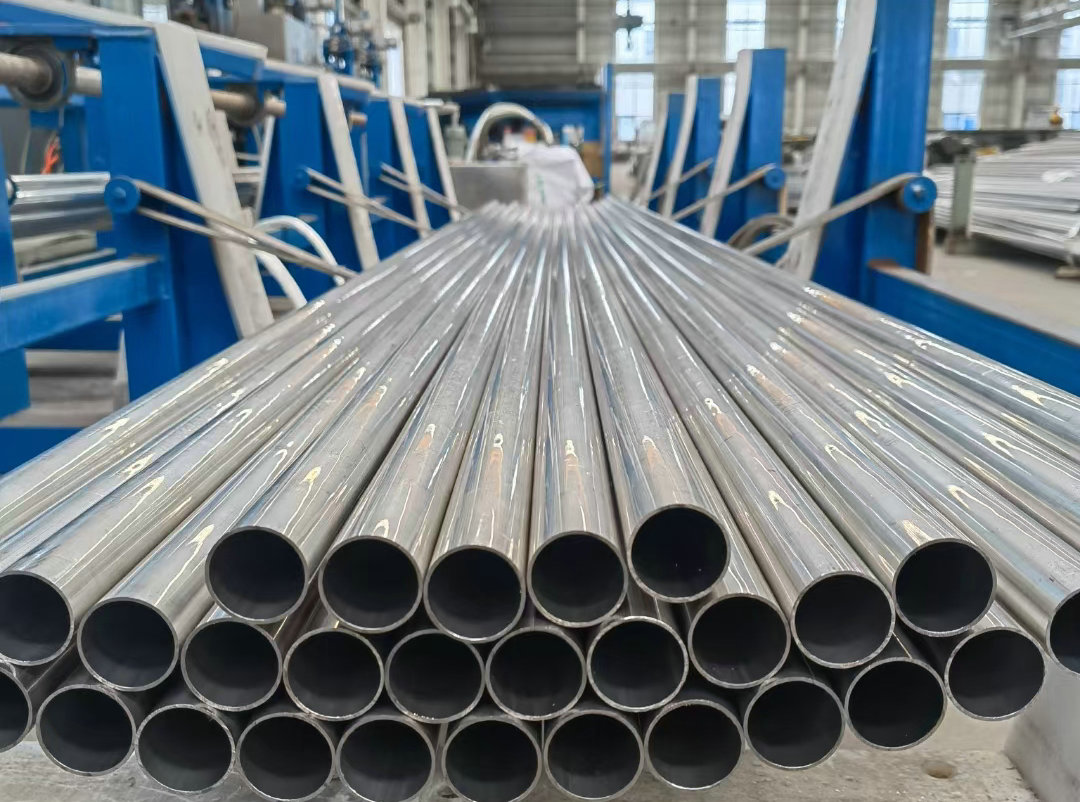

Nascent Pipe & Tubes is a leading manufacturer, supplier, and exporter of high-quality Super Duplex S32760 Pipes, known for their superior mechanical strength and excellent corrosion resistance in extreme environments. These pipes are crafted using the finest quality raw materials and advanced manufacturing technology to ensure reliability in the most challenging industrial applications. Super Duplex S32760, designated under the UNS number UNS S32760, is a highly alloyed, super duplex stainless steel developed for applications requiring exceptional strength and resistance to chloride-induced stress corrosion cracking.

At Nascent Pipe & Tubes, we offer Super Duplex Steel S32760 Pipes that comply with globally recognized standards such as ASTM A790 for seamless and straight-seam welded ferritic/austenitic stainless steel pipes, and ASTM A928 for electric-fusion-welded duplex stainless steel pipes. These standards ensure that our pipes meet stringent quality, mechanical, and dimensional requirements, making them ideal for use in critical industrial operations. Our pipes come in various sizes, thicknesses, and schedules, fully customizable to meet client-specific needs.

Super Duplex S32760 Pipes Manufacturers, Super Duplex S32760 Pipes Suppliers, Super Duplex S32760 Pipes Stockists, Super Duplex S32760 Pipes Exporters

Super Duplex S32760 Pipes Manufacturers in India, Super Duplex S32760 Pipes Suppliers in India, Super Duplex S32760 Pipes Stockists in India, Super Duplex S32760 Pipes Exporters in India

Our Super Duplex S32760 Pipes are produced with exact control over the chemical composition, involving a large proportion of chromium (24–26%), molybdenum (3–4%), and nitrogen. All these contribute to the excellent corrosion resistance feature of the material, particularly in chloride-containing and seawater applications. We supply the following pipes at Adinox Overseas in the form of seamless, welded, and ERW to accommodate different design requirements and pressure ratings. They are compliant with prominent international standards like ASTM A790 for seamless and welded super duplex stainless steel pipe and ASTM A928 for welded pipes by electric fusion welding with a filler metal.

Super Duplex S32760 Pipes Manufacturers in Mumbai, Super Duplex S32760 Pipes Suppliers in Mumbai, Super Duplex S32760 Pipes Stockists in Mumbai, Super Duplex S32760 Pipes Exporters in Mumbai

The special properties that these Super Duplex S32760 Pipes & Tubes possess make huge demands for them in different sectors. They are especially good for those applications that require excellent resistance to pitting and crevice corrosion, along with stress corrosion cracking. Nascent Pipe & Tubes are known to be well-recognized stockists and thus store these pipes and tubes in vast amounts in larger sizes and various specifications so as to make sure that the clients get the appropriate product for use in a specific application.

Specification of Duplex Steel S32760 Seamless / Welded Pipes

Specifications AASTM A790 / ASME SA790, ASTM A789 / ASME SA A789

Grade : UNS S32760

Size : ½”NB – 24”NB

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Outer Diameter: 6.0-630mm

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Duplex Steel Pipes

| C | Cr | Ni | Mo | N | Other |

|---|---|---|---|---|---|

| 0.020 | 25 | 7 | 4.0 | .27 | S=0.001 |

Mechanical Properties Of Duplex Steel Seamless & Welded Pipes

| Ultimate Tensile Strength, ksi | 116 min. |

|---|---|

| 0.2% Offset Yield Strength 0.2%, ksi | 80 min. |

| 0.1% Offset Yield Strength 0.2%, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness Rockwell C | 32 max. |

| Impact Energy, ft.-lbs. | 74 min. |

Physical Properties of S32760 Duplex Steel Pipes

| Density | lb/in3 | 0.28 |

|---|---|---|

| Modulus of Elasticity | psi x 106 | 29 |

| Coefficient of Thermal Expansion 68-212°F/°F | x10-6/°F | 7.2 |

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Heat Capacity | Btu/lb/°F | 0.12 |

| Electrical Resistivity | W-in x 10-6 | 31.5 |

Our Export

Domestic Area

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |