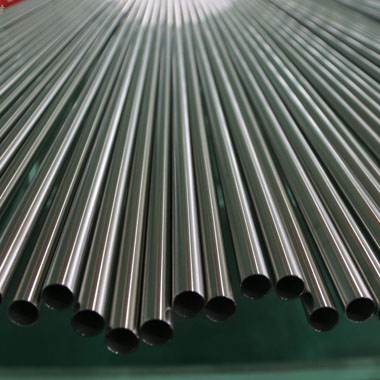

Nascent Pipe & Tubes is a globally trusted supplier and manufacturer of Super Duplex S32750 Tubes, offering precision-engineered tubing solutions for critical industrial applications. These tubes are made using high-quality Super Duplex stainless steel grade UNS S32750, conforming to ASTM A789 for seamless and welded ferritic/austenitic stainless steel tubing, as well as ASTM A790 for pipe specifications. Known universally by the standard name Super Duplex 2507, these tubes are developed to offer exceptional mechanical properties and resistance to highly corrosive environments.

Super Duplex S32750 is a nitrogen-enhanced duplex stainless steel that combines the desirable aspects of both ferritic and austenitic grades. The alloy exhibits outstanding pitting resistance equivalent number (PREN > 42.5), making it ideal for highly saline and chloride-rich environments. With excellent resistance to stress corrosion cracking, crevice corrosion, erosion, and fatigue, UNS S32750 Tubes are extensively used in marine industries, offshore platforms, desalination plants, heat exchangers, oil & gas pipelines, and power generation sectors.

Super Duplex S32750 Tubes Manufacturers, Super Duplex S32750 Tubes Suppliers, Super Duplex S32750 Tubes Stockists, Super Duplex S32750 Tubes Exporters

Super Duplex S32750 Tubes Manufacturers in India, Super Duplex S32750 Tubes Suppliers in India, Super Duplex S32750 Tubes Stockists in India, Super Duplex S32750 Tubes Exporters in India

At Nascent Pipe & Tubes, our ASTM A789 S32750 Tubes and ASTM A790 S32750 Tubes are manufactured under strict quality control to meet global standards and client-specific requirements. The tubes offer superior yield strength, double that of standard austenitic grades, and provide long-term operational stability even in harsh conditions. These tubes also deliver excellent weldability and workability, making them suitable for fabrication and custom-engineered applications.

Super Duplex S32750 Tubes Manufacturers in Mumbai, Super Duplex S32750 Tubes Suppliers in Mumbai, Super Duplex S32750 Tubes Stockists in Mumbai, Super Duplex S32750 Tubes Exporters in Mumbai

The high chromium (25%), molybdenum (4%), and nitrogen content of UNS S32750 Super Duplex Tubes ensures low thermal expansion, excellent resistance to localized corrosion, and longer service life. Our tubes are widely accepted in chemical processing industries, subsea equipment, pressure vessels, and other aggressive media applications. Nascent Pipe & Tubes takes pride in being a reliable export partner, offering timely deliveries across the globe. Our technical team provides complete documentation, including third-party inspection certificates, test reports, and compliance records, ensuring full traceability.

Specification of Duplex Steel S32750 Seamless / Welded Tubes

Specifications AASTM A790 / ASME SA790, ASTM A789 / ASME SA A789

Grade : UNS S31803, S32205

Size : ½”NB – 24”NB

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Outer Diameter: 6.0-630mm

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Duplex Steel Tubes

| Grade | Common Name | C% | Mn% | Si% | P% | S% | Cr% | Ni% | Mo% | N% |

|---|---|---|---|---|---|---|---|---|---|---|

| S32750 | S32750 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

Mechanical Properties Of Duplex Steel Seamless & Welded Tubes

| Tensile Strength, ksi | 90 min |

|---|---|

| 0.2% Yield Strength, ksi | 65 min |

| Elongation, % | 25 min |

| Hardness [HRC] | 293 max |

Physical Properties of UNS S32750 Duplex Steel Tubes

| Density lbm/in3 | Electrical Resistivity mW•in | Thermal Conductivity (BTU/hr•ft•°F) | Heat Capacity BTU/lbm•°F | Electrical Resistivity (in x 10-6) | |

|---|---|---|---|---|---|

| at 68°F | 0.278 | 27.6 | 8.7 | 0.112 | 33.5 |

| at 212°F | 26.1 | 9.2 | 0.119 | 35.4 | |

| at 392°F | 25.4 | 9.8 | 0.127 | 37.4 | |

| at 572°F | 24.9 | 10.4 | 0.134 | 39.4 |

Equivalent Grades Of Duplex Stainless Steel Tubes

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Super Duplex 2507 | 1.4410 | S32750 |

Our Export

Domestic Area

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |